Article updated on January 18, 2026

Text & Photographs: Claire Lessiau & Marcella van Alphen

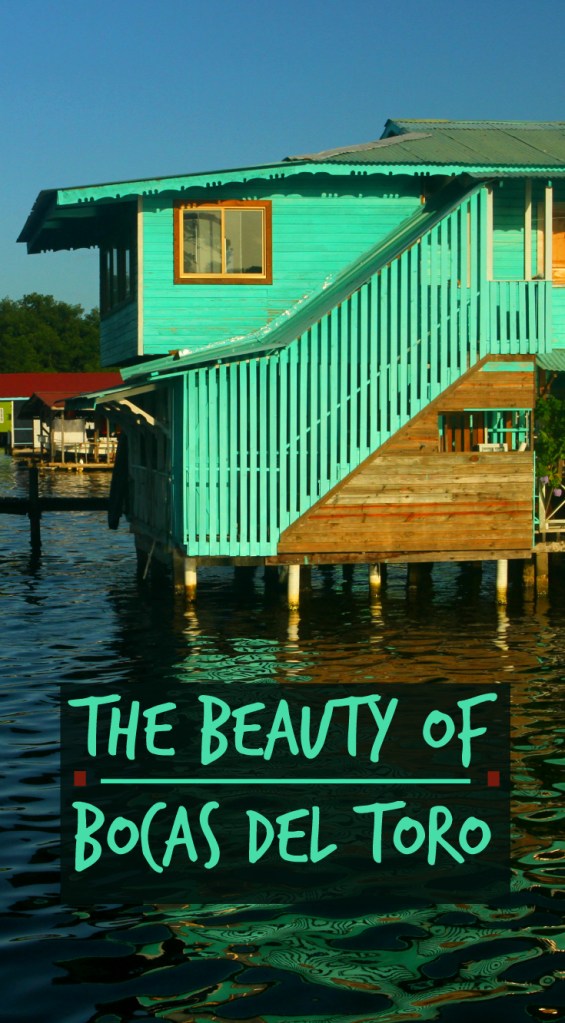

The Bocas del Toro archipelago in Panama is world-renowned for its stunning beaches and islands, surfing and snorkelling spots. And there is one more reason to go to Bocas: the mountainous forests on the mainland by the harbour town of El Almirante are home to one of the best organic cacao producers in the world!

From El Almirante where we got off the boat from Bocas. The road gets narrower and winds up through the dense forest of bamboos and banana trees to end by an indigenous Ngobe community of about 700 spread along the mountain slopes. From there, we go on foot and hike the steep hill towards the cacao trees with our guide, Pablo.

Along the way, passing a few houses, he explains what the trees we come across are used for by the Ngobes who live close to nature: the dragon wood is used for its juice, the breadfruit is boiled and eaten as a potato-like side, the cedar wood is burnt to keep mosquitos away… It gets steeper, and Pablo stops: the cacao tree plantation starts here.

We contemplate the view on the mountains. “There are about 60 varieties of cacao trees, but to ensure the best taste and year-round production, only 3 of them are used.” The Criollo is favoured as its cacao is one of the finest with the most complex taste of vanilla, nuts and tobacco. But it is blended, as different varieties of cacao trees are planted to make them more resilient: “fungus has been destroying about 85% of the pods”, Pablo explains with a sad look. A delicate balance of shade, to ensure the cacao flowers do not burn, and sun, to dry the humidity and limit the progression of the fungus is reached by planting higher trees on the land. Pruning and trimming are essential, and this is an everyday task for the farmers.

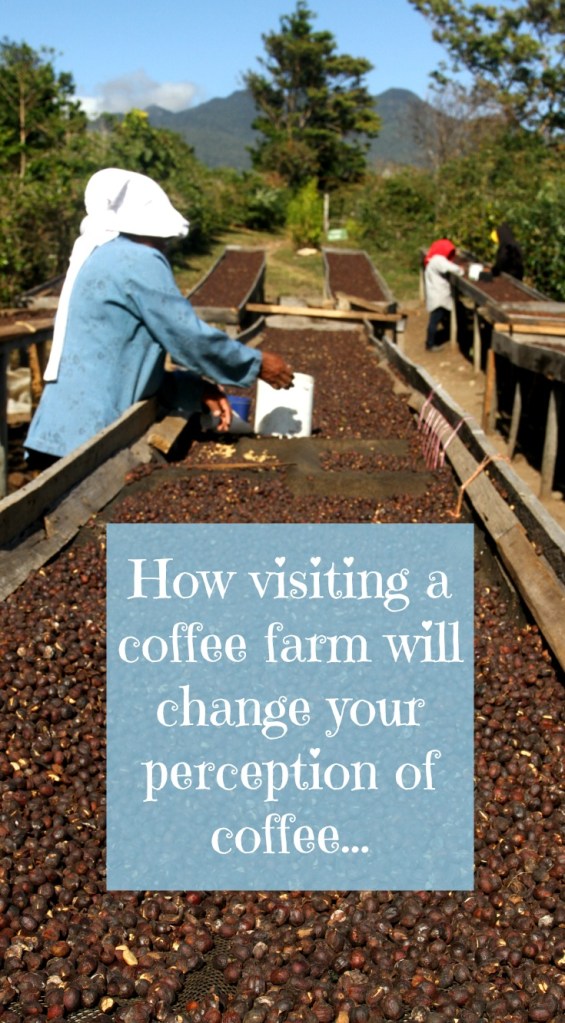

On our way back down, we pass by a few greenhouses. “When we open the cacao pods, we need to ferment them to prevent germination. The process is completely natural, putting the beans with the mucilage between two layers of banana leaves, and in about 5 days, they reach the desired temperature of 50°C: they turn brown and have a characteristic smell of fermentation. Then, they are put to dry in the greenhouse for about 9 days. If we mess up, the quality goes down and we can only sell them for half the price.” Pablo explains.

In a small clearing, a Ngobe woman dressed in a traditional pink dress is standing by a pan on an open fire and a grinding stone. Pablo breaks open a ripe cacao pod. The mucilage, the white fluffy substance surrounding the brown beans tastes sweet. He drops a few beans in the pan and the woman stirs. They start to pop: they are ready. We peel off the warm skin, dehusking them before tasting 100 percent pure cacao. It is powerful and bitter! The woman smiles and adds a bit of brown sugar to the paste she has been grinding on the stone. We spoon it out. That’s more like it! “That’s 95% cacao”, Pablo specifies enthusiastically.

As a chocolate addict, understanding what it takes to grow and produce cacao makes me appreciate it even more. This specific cacao grown in Northern Panama is mainly exported to Switzerland. There, it is processed to become one of the best chocolates in the world.

Travel tips:

- To live this experience, contact Oreba in Rio Oeste Arriba.

- Isn’t chocolate even better with a coffee… And what about not eny coffee, but one of world’s best growing close-by? Check this out!

- Check out this interactive map for the specific details to help you plan your trip and more articles and photos (zoom out) about the area!

For more in Panama, click on these images:

I’m a chocolate addict! This tour seems right up my alley. Another thing to add to my bucket list 🙂